Wide Belts

MOQ : 1 Piece

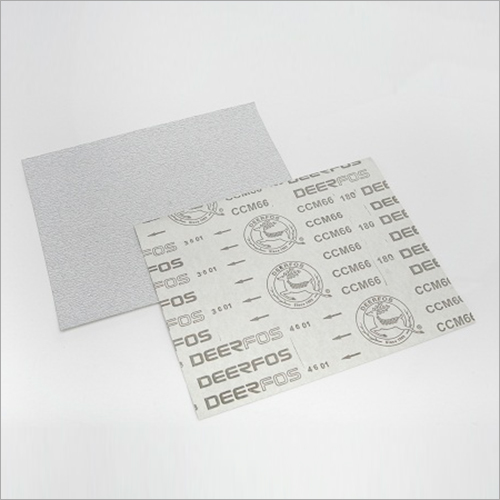

Wide Belts Specification

- Backing

- Cloth, polyester, paper

- Hardness

- Medium to hard

- Chemical Composition

- Varies by grain type: (Al2O3, SiC, ZrO2)

- Shape

- Rectangular belt

- Grain Type

- Aluminum oxide, Silicon carbide, Zirconia

- Bonding

- Resin bonded

- Toughness

- High

- Material

- Abrasive cloth, abrasive paper

- Type

- Wide belt

- Grain Sizes

- P24 to P400

- Rolls Size

- Customized as per requirement

- Strips Size

- Available in various widths and lengths

- Color

- Brown, blue, green or as per abrasive type

- Length Range

- Up to 4000 mm or as required

- Joint Types

- Overlapped, butt joint, taped joint

- Application

- Woodworking, metalworking, glass, stone polishing

- Maximum Width

- Up to 1350 mm

- Temperature Resistance

- Up to 200°C

- Coating

- Close coat, open coat

- Surface Finishing

- Polished, sanded

- Grit Type

- Coated abrasive

Wide Belts Trade Information

- Minimum Order Quantity

- 1 Piece

- Payment Terms

- Cash in Advance (CID), Cash Advance (CA)

- Supply Ability

- 100 Pieces Per Day

- Delivery Time

- 1-2 Days

- Sample Available

- Yes

- Sample Policy

- Sample costs shipping and taxes has to be paid by the buyer

- Packaging Details

- Carton Box

- Main Export Market(s)

- Australia, North America, Eastern Europe, Middle East, Central America, Africa, South America, Western Europe, Asia

- Main Domestic Market

- All India

About Wide Belts

Backed by an adept team of professionals, we are offering a wide assortment of Wide Belts. Fine finish, light weight, easy installation and accurate dimensions are qualities of offered product. This product is designed and manufactured at our advanced production unit using advanced technology and quality approved materials that are sourced from reliable vendors of the industry in adherence with set market quality standards. The offered Wide Belts are used in textile and garment industry. Along with this, we provide these products at rock bottom prices to our esteemed clients.

Precision-Engineered for Maximum Versatility

Our wide belts cater to diverse industries such as woodworking, metalworking, and glass or stone finishing. The belts are available in different joint types and widths, providing outstanding customization and seamless integration into your production processes.

Customizable Sizes and Grits for Every Application

Choose from an impressive range of belt widths up to 1350 mm and lengths tailored to your needs. Grain sizes run from P24 to P400, ensuring optimal performance whether you require aggressive material removal or fine surface finishing.

Reliable Durability and Heat Resistance

Manufactured from premium abrasive materials, our belts withstand temperatures up to 200C and are crafted for high toughness and durability. The variety in backing and bonding materials enhances the belts longevity and adaptability.

FAQs of Wide Belts:

Q: How are wide belts with widths up to 1350 mm typically used in woodworking and metalworking?

A: These wide belts are designed for high-efficiency sanding, deburring, and polishing in woodworking and metalworking operations. Their broad coverage allows for even and consistent finishing on large surfaces.Q: What materials are used in the construction of these wide belts?

A: The belts are made from abrasive cloth or paper, often backed with cloth, polyester, or paper. Grains such as aluminum oxide, silicon carbide, and zirconia are used, bonded with resin for optimal strength and performance.Q: When should I choose a close coat versus an open coat belt?

A: Close coat belts are ideal for fine surface finishing on hard materials, as the abrasive covers most of the belts surface. Open coat belts, with spaced abrasive grains, are better for softer or resinous materials where loading is a concern.Q: Where can I source these wide belts, and are custom sizes available?

A: These belts can be sourced through authorized distributors, suppliers, and traders across India. We offer customization in width, length, grain size, and joint type to fit your equipment and processing needs.Q: What are the benefits of the resin-bonded abrasive belts with temperature resistance?

A: Resin-bonded belts provide superior grain adhesion and durability, allowing the belts to perform reliably at temperatures up to 200C. This ensures consistent finishing results with minimal belt degradation.Q: How does the choice of grain type (Al2O3, SiC, ZrO2) affect the belts performance?

A: Aluminum oxide (Al2O3) offers general-purpose use with moderate hardness and toughness. Silicon carbide (SiC) provides sharper cutting action for hard or brittle materials, while zirconia (ZrO2) delivers high toughness and longevity for heavy-duty applications.Q: What process is used to join wide belts, and how does it impact application?

A: Wide belts can be joined using overlapped, butt, or taped joints. The choice of joint affects the belts strength, flexibility, and suitability for different machines and applications, allowing seamless performance even in demanding environments.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

|

TOOLS - N - ABRASIVES

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry