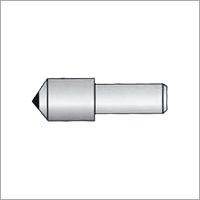

Diamond Indenters

MOQ : 1 Piece

Diamond Indenters Specification

- Shape

- Pyramidal, conical, or sphero-conical shapes

- Chemical Composition

- Pure diamond (C), metal shank varies (typically steel or tungsten carbide)

- Hardness

- Exceeds 8000 HV (Vickers hardness)

- Bonding

- High-strength brazing or bonding with metal matrix

- Toughness

- High fracture resistance, specifically engineered for impact

- Backing

- Mounted on steel or tungsten carbide holders

- Grain Type

- Mono-crystalline or polycrystalline diamond

- Material

- Natural diamond or synthetic diamond

- Type

- Vickers, Knoop, Rockwell, Brinell indenters

- Grain Sizes

- Fine to coarse grain options available

- Rolls Size

- Standard and custom sizes available upon request

- Strips Size

- Customized as per instrument requirements

- Life Expectancy

- Designed for extended operational life above 50,000 cycles

- Tip Radius

- Below 0.5 microns, precision polished

- Surface Finish

- Mirror polished tip for consistent indentations

- Heat Resistance

- Withstands prolonged testing at standard laboratory temperatures

- Accuracy Class

- Guaranteed within +/- 0.5 micron

- Packaging

- Individually packed in protective casing

- Application

- Microhardness and macrohardness testing instruments

Diamond Indenters Trade Information

- Minimum Order Quantity

- 1 Piece

- Payment Terms

- Cash in Advance (CID), Cash Advance (CA)

- Supply Ability

- 100 Pieces Per Day

- Delivery Time

- 1-2 Days

- Sample Available

- Yes

- Sample Policy

- Sample costs shipping and taxes has to be paid by the buyer

- Packaging Details

- Carton Box

- Main Export Market(s)

- Australia, South America, Western Europe, Middle East, Central America, Asia, Eastern Europe, North America, Africa

- Main Domestic Market

- All India

About Diamond Indenters

Our company offers highly durable and robust Diamond Indenters that can be used in industrial and construction applications to test hardness of various engineering materials. It is also helpful to determine wear-resistance and strength of work pieces. The holder of this unit is made up by using premium quality mild steel that provides high strength and rigidity to bear extreme loads and vibrations. The hardness is determined as per the size and shape of indentation created. Get this industrial at a reasonable price.

Features:

- Light weight

- High strength

- Sturdiness

- Rust resistance

Exceptional Precision and Durability

Our diamond indenters are mirror polished with a tip radius under 0.5 microns, ensuring reliable and highly accurate hardness measurements. Resistant to wear and designed for longevity, they satisfy the needs of demanding lab environments, withstanding over 50,000 test cycles while maintaining precision within +/- 0.5 microns.

Versatile Shapes and Customization Options

Multiple geometriespyramidal, conical, or sphero-conicalsupport a diverse range of hardness testing methods, including Vickers, Knoop, Rockwell, and Brinell. Customization is available for roll and strip sizes, grain configurations, and bonding styles to ensure compatibility with all major microhardness and macrohardness testing instruments.

Robust Construction and Secure Packaging

Manufactured from natural or synthetic diamond, each indenter is securely bonded to either steel or tungsten carbide holders for maximum strength and fracture resistance. The individual protective casing guards the mirror-polished tip during shipping and storage, preserving the integrity required for precise hardness testing.

FAQs of Diamond Indenters:

Q: How are diamond indenters with tip radii below 0.5 microns used in testing applications?

A: These diamond indenters are primarily used in microhardness and macrohardness testing instruments, such as Vickers, Knoop, Rockwell, and Brinell testers. Their precision mirror-polished tips ensure consistent, repeatable indentations for accurate hardness measurement of various materials.Q: What is the benefit of a mirror-polished tip on diamond indenters?

A: A mirror-polished tip provides a smooth, flawless surface that reduces surface artifacts and ensures uniform indentation results. This is critical for achieving highly reproducible and reliable hardness measurements in laboratory testing environments.Q: What customization options are available for diamond indenters?

A: Customers can select from a variety of shapes (pyramidal, conical, sphero-conical), grain sizes (fine to coarse), grain types (mono-crystalline or polycrystalline), and mounting options. Standard and custom sizing for rolls and strips can be provided to match specific instrument requirements.Q: What materials are used in the construction of these diamond indenters?

A: The indenters are fabricated using either natural or synthetic diamond, with a pure carbon composition for the tip. The diamond is securely bonded to a metal shank, typically made from steel or tungsten carbide, to enhance strength and fracture resistance.Q: How does the product withstand prolonged testing and varying conditions?

A: Engineered for high durability, each indenter can endure extended operational life above 50,000 cycles without loss of accuracy. Their superior hardness (exceeds 8000 HV) and robust backing confer excellent heat and impact resistance during standard laboratory testing conditions.Q: Where are these diamond indenters distributed or supplied?

A: These diamond indenters are supplied, distributed, and traded through trusted distributors in India, ensuring they meet the needs of laboratories and industries involved in material hardness testing across the country.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

|

TOOLS - N - ABRASIVES

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry