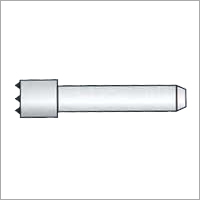

Cluster Dressers

MOQ : 1 Piece

Cluster Dressers Specification

- Grain Type

- Natural/Synthetic Diamond

- Chemical Composition

- Diamond with metal matrix

- Toughness

- High toughness for extended tool life

- Shape

- Cluster

- Bonding

- Metal Bonded

- Hardness

- High hardness suitable for dressing wheels

- Backing

- Steel body

- Material

- Diamond Grit

- Type

- Cluster Dresser

- Grain Sizes

- 40/50 to 325/400 mesh

- Rolls Size

- Customized as per requirement

- Strips Size

- Varies as per application

- Shank Diameter

- Varies as per order/specification

- Surface Finish Quality

- Provides precise and consistent finish

- Customization

- Available as per customer drawing and requirement

- Weight

- Depends on model and size

- Application

- Dressing and truing of grinding wheels

- Suitable Machines

- Cylindrical, Surface and Centerless Grinders

- Operating Speed

- Recommended as per grinding wheel manufacturer

- Working Life

- Long service life due to cluster diamond design

- Dressing Tool Type

- Single point and multipoint cluster dresser

Cluster Dressers Trade Information

- Minimum Order Quantity

- 1 Piece

- Payment Terms

- Cash in Advance (CID), Cash Advance (CA)

- Supply Ability

- 100 Pieces Per Day

- Delivery Time

- 1-2 Days

- Sample Available

- Yes

- Sample Policy

- Sample costs shipping and taxes has to be paid by the buyer

- Packaging Details

- Carton Box

- Main Export Market(s)

- Western Europe, Australia, North America, Eastern Europe, Central America, Africa, Middle East, South America, Asia

- Main Domestic Market

- All India

About Cluster Dressers

We are offering highly durable and robust Cluster Dressers designed to perform dressing and shaping of grinding wheels. It is installed with clusters of small diamond grits bonded together in specific pattern to provide optimal dressing results. It is commonly used in metalworking, woodworking, and glass working applications. It greatly improves the productivity as well as reduces downtime. Buyers can this industrial grade tool with an assurance of fast and safe delivery.

Other Details :- The Cluster Type Diamond Dresser is ideal for coarse or rough dressing of grinding wheels in sizes up to 80 grit.

- The diamonds can be fully utilised without re-setting or re-sharpening.

- Dressing costs are substantially reduced as the diamonds used in this type of dressers are much smaller in size than Single Point Diamond Dresser.

- The dressing face of the Cluster Type Diamond Dresser should be set at an angle of 90 degree to the grinding wheel so that all the diamond points are in contact at the same time.

Precision Dressing for Enhanced Grinding

Cluster Dressers excel in achieving uniform wheel surfaces, greatly improving the results in grinding operations. The cluster diamond configuration guarantees extended working life, while the tools adaptability allows use across various grinder types. For processes demanding consistent finish and exact tolerances, these dressers are an excellent choice.

Customizable Design for Diverse Applications

With options for custom shank diameter, strip sizes, roll dimensions, and grain sizes between 40/50 and 325/400 mesh, Cluster Dressers can be tailored to specific machine setups and operational requirements. Both natural and synthetic diamonds are utilized, all securely bonded to a robust steel backing for optimum durability.

FAQs of Cluster Dressers:

Q: How are Cluster Dressers used for grinding wheel dressing?

A: Cluster Dressers are attached to cylindrical, surface, or centerless grinders and applied to the grinding wheels surface to reshape, clean, and restore its cutting effectiveness. The process is performed at operating speeds recommended by the grinding wheel manufacturer.Q: What is the benefit of using a cluster diamond design in these dressers?

A: The cluster diamond design distributes wear across multiple points, resulting in a longer working life, improved durability, and a more consistent finish on the grinding wheel compared to single-point dressers.Q: When should I consider using a customized Cluster Dresser?

A: Custom Cluster Dressers are ideal when you have specific requirements such as unique shank diameters, roll sizes, or grain configurations needed to match your grinding machine and application demands.Q: Where can Cluster Dressers be used?

A: These dressers are suitable for use on cylindrical, surface, and centerless grinding machines in industrial settings, especially where high precision and consistent surface finish are critical.Q: What materials are used in the manufacturing of Cluster Dressers?

A: Cluster Dressers are made from high-toughness natural or synthetic diamond grit embedded in a metal matrix and supported by a steel body for enhanced strength and durability.Q: How does the hardness and toughness of Cluster Dressers affect their performance?

A: The high hardness and toughness of the diamonds ensure that the tool can efficiently dress and true even very hard grinding wheels, prolonging tool life and maintaining consistent performance throughout its use.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

|

TOOLS - N - ABRASIVES

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry