Bonded Abrasive

Price 100 INR/ Piece

MOQ : 100 Pieces

Bonded Abrasive Specification

- Chemical Composition

- Al2O3 (Aluminum Oxide), bonding agents

- Bonding

- Vitrified

- Hardness

- High

- Toughness

- Excellent durability

- Shape

- Round (Wheel)

- Grain Type

- Coated abrasive

- Backing

- Fiberglass or resin

- Material

- Aluminum Oxide

- Type

- Bonded Abrasive

- Grain Sizes

- Available in various grits

- Thickness

- Ranges from 6 mm to 25 mm

- Application

- Grinding and finishing of metals, steels, and cast iron

- Portability

- Stationary and hand-held tool compatible

- Color

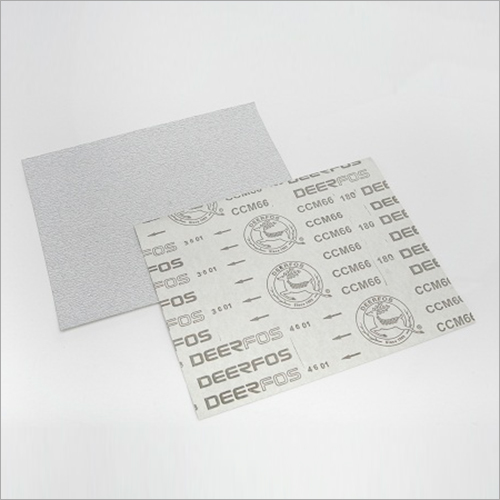

- Brown/Grey

- Operating Speed

- Max 35 m/s

- Diameter

- 100 mm, 125 mm, 150 mm, 180 mm, or as specified

Bonded Abrasive Trade Information

- Minimum Order Quantity

- 100 Pieces

- Supply Ability

- 1000 Pieces Per Day

- Delivery Time

- 2 Days

About Bonded Abrasive

We are one of the big names that deal in supplying of industrial class Bonded Abrasive wheel which is commonly used for grinding and cutting of heavy duty materials such as metals, marbles, ceramics, and many more with high precision and accuracy. It is available in disc and cylindrical shapes that can be delivered to our clients as per their demands. Buy from us this heavy duty machining tool at a low price.

Features:

- Highly durable

- Easy to fit

- Excellent strength

- Impeccable finish

Versatile Solutions for Metal Grinding

Engineered for excellence, these bonded abrasive wheels are compatible with both hand-held and stationary tools, making them suitable for various environments, from workshops to large-scale manufacturing units. Their high hardness, excellent toughness, and vitrified bonding deliver consistent performance for grinding, deburring, and finishing tasks.

Precision in Performance and Safety

Operating smoothly at speeds up to 35 m/s, our abrasive wheels combine fiberglass or resin backings for outstanding stability. The robust chemical composition ensures minimal wear and maximizes service life, reducing the need for frequent replacements and increasing productivity.

FAQ's of Bonded Abrasive:

Q: How should I select the correct diameter and thickness for my grinding application?

A: Choosing the appropriate diameter (100 mm, 125 mm, 150 mm, 180 mm, or as specified) and thickness (6 mm to 25 mm) depends on your machine's compatibility and the material's surface area. Thicker wheels are ideal for heavy stock removal, while thinner ones suit finer finishing.Q: What are the main benefits of using bonded abrasive wheels with aluminum oxide grains?

A: Aluminum oxide grains provide high hardness and toughness, ensuring excellent durability and cutting efficiency. This makes the wheels effective for grinding and finishing metals, steels, and cast iron, delivering consistent results and extended wheel life.Q: When should bonded abrasive wheels be replaced?

A: Wheels should be replaced when their diameter falls below the manufacturer's safety limits, if there is visible damage such as cracks, or if there is noticeable loss in cutting or grinding efficiency. Regular inspection is vital to ensure safe and optimal use.Q: Where can these abrasive wheels be used effectively?

A: They are suitable for workshops, fabrication facilities, metal finishing plants, and industrial sites that handle steel or cast iron. Their compatibility with stationary machines and portable tools offers ample flexibility across various locations.Q: What is the process for mounting these wheels on a tool?

A: Begin by inspecting the wheel for damage. Match the wheel's size with your tool's spindle and follow the manufacturer's installation instructions. Always use the recommended flanges and avoid overtightening to prevent cracks. Conduct a trial run at operating speed before starting work.Q: How do vitrified bonds improve wheel performance?

A: Vitrified bonding provides excellent rigidity and heat resistance, allowing the wheel to maintain shape and structure during demanding grinding operations. This ensures precise metal removal and longer service life, even under high-stress conditions.Q: What safety precautions should I take when using these bonded abrasives?

A: Always wear personal protective equipment such as safety goggles, gloves, and hearing protection. Ensure proper mounting, operate within the maximum speed of 35 m/s, and inspect wheels before use to prevent accidents.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Topline Category

Roll Grinding Wheel

Price 90 INR / Piece

Minimum Order Quantity : 100 Pieces

Material : Aluminum Oxide

Toughness : High

Grain Sizes : Fine

Chemical Composition : Silicon Carbide

|

TOOLS - N - ABRASIVES

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry