Non-Ferrous Metal Glass Working

Non-Ferrous Metal Glass Working Specification

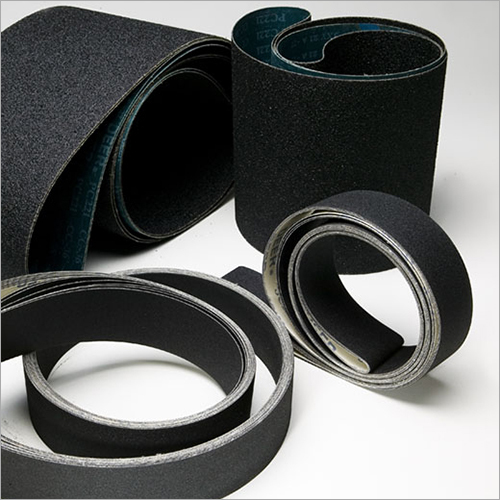

- Shape

- Rolls, Strips

- Toughness

- High Toughness for Glass Applications

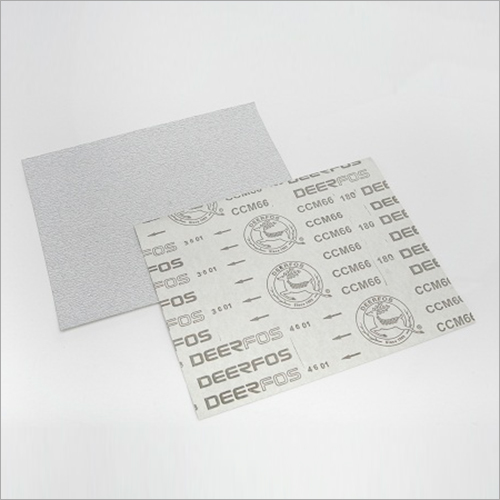

- Grain Type

- Aluminium Oxide or Silicon Carbide

- Backing

- Glass Fibre Reinforced

- Hardness

- Medium to Hard

- Bonding

- Resin Bonded

- Chemical Composition

- Non-Ferrous Alumina, Glass Fibre, Phenolic Resin

- Material

- Non-Ferrous Metal Oxide, Glass Fibre base

- Type

- Glass Working Abrasive

- Grain Sizes

- P36 to P800

- Rolls Size

- 100 mm to 350 mm (width) x up to 50 m (length)

- Strips Size

- 15 mm, 20 mm, 25 mm, 30 mm, 40 mm, 50 mm, Cut-to-length available

- Applications

- Glass polishing, edge honing, deburring of non-ferrous metals

- Storage Conditions

- Dry and Cool Location

- Feature

- Flexible backing for curved surfaces

- Temperature Resistance

- Up to 200°C

- Thickness Range

- 0.6 mm to 1.2 mm

- Width Tolerance

- ±1 mm

- Maximum Operating Speed

- Up to 40 m/s

- Colour

- Brown, Black, Grey

- Coating

- Open and Closed Coating available

Non-Ferrous Metal Glass Working Trade Information

- Minimum Order Quantity

- 1 Piece

- Payment Terms

- Cash in Advance (CID), Cash Advance (CA)

- Supply Ability

- 100 Pieces Per Day

- Delivery Time

- 1-2 Days

- Sample Available

- Yes

- Sample Policy

- Sample costs shipping and taxes has to be paid by the buyer

- Packaging Details

- Carton Box

- Main Export Market(s)

- Western Europe, Australia, South America, Eastern Europe, Middle East, Africa, Asia, Central America, North America

- Main Domestic Market

- All India

About Non-Ferrous Metal Glass Working

Non-Ferrous Metal Glass Working belt offered by our company is flexible and highly durable grinding and surface finishing tool that is commonly used in medium to heavy duty applications such as grinding and surface finishing. It comes in various lengths and widths that can be customized as per the order placed by our customers. It is suitable for metallic as well as non-metallic work parts. The offered belt can be delivered to our clients with an assurance of fast and safe delivery.

Versatile Solutions for Glass & Metal Finishing

Engineered for demanding glass working applications, these abrasives deliver exceptional performance in polishing, edge honing, and deburring tasks. The flexible glass fibre backing adapts to curved or irregular surfaces, making them perfect for artisanal as well as industrial use. With a wide grain size range, various thicknesses, and customizable strip sizes, users can match products to their specific project requirements with ease.

Superior Durability and Operating Efficiency

Our abrasives utilize robust non-ferrous alumina grains, phenolic resin bonding, and glass fibre reinforcement, resulting in high toughness and resilience at elevated temperatures. Whether operating at speeds up to 40 m/s or under continuous use, these products maintain integrity and function, ensuring smooth, efficient, and repeatable results across multiple workloads.

Flexible Sizing Options for Every Need

Available in widths from 100 mm to 350 mm and cut-to-length strips between 15 mm and 50 mm, our abrasives offer unmatched adaptability. Rolls come up to 50 meters long, with precise width tolerances of 1 mm. From small-scale workshops to large manufacturing setups, these abrasives fit seamlessly into diverse operations, simplifying inventory and workflow.

FAQs of Non-Ferrous Metal Glass Working:

Q: How should these non-ferrous metal glass working abrasives be stored for optimal preservation?

A: Store the abrasives in a dry and cool environment to prevent moisture or temperature-related damage. Proper storage ensures the material retains its flexibility, grain effectiveness, and durability for longer periods.Q: What is the recommended usage process for glass polishing or edge honing with these abrasives?

A: Select an appropriate grain size between P36 and P800 based on the desired finish. Use on compatible machines or by hand, keeping to a maximum speed of 40 m/s. Flexible backing allows conformance to curves during polishing or honing applications, delivering a smooth, even result.Q: When should open or closed coated abrasives be chosen for best performance?

A: Opt for open coated types when working on softer surfaces or where rapid stock removal and reduced clogging are needed. Closed coating suits harder materials and finer finishing, providing a slightly more aggressive cut and smoother result.Q: Where can these abrasives be effectively applied?

A: They are primarily suitable for glass polishing, edge honing, and deburring non-ferrous metals in artisanal, industrial, or workshop environments. The products flexibility and toughness also make it ideal for use on contoured or curved surfaces.Q: What benefits do glass fibre reinforced backings provide during use?

A: The glass fibre reinforcement enhances flexibility and strength, ensuring the abrasive can conform to complex shapes without cracking or breaking. This allows consistent contact during polishing or deburring, improving surface finish and user control.Q: How does one select the right thickness and width for a specific task?

A: Select a thickness in the range of 0.6 mm to 1.2 mm according to the applications intensity, with thicker options offering more rigidity. Choose widths between 100 mm and 350 mm for rolls or strips from 15 mm to 50 mm. Consider cut-to-length options for custom fitting to your tools or machines.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Non-Ferrous Metal, Glass Working Category

Non-Ferrous Metal Glass Working

Minimum Order Quantity : 1 Piece

Usage : For Grinding

Shape : Rectangle

Type : Non ferrous

Color : Black

Material : Fiber

Non-Ferrous Metal Glass Working

Minimum Order Quantity : 1 Piece

Usage : For Grinding

Shape : Stripe

Type : Non Ferrous

Color : Black

Material : Fiber

|

TOOLS - N - ABRASIVES

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry